When it comes to the food industry, safety and hygiene are of utmost importance. Business owners must carefully consider the materials they use in their production line, from packaging to transportation equipment. A significant aspect of this consideration is the conveyor belts, an essential part of the food processing line.

So, which conveyor belts are best for food safety: metal or PVC? This question is more than just a matter of preference. It directly influences food safety standards, production efficiency, and overall product quality. We aim to provide a clear comparison between metal and PVC belting so you can make an informed decision regarding your manufacturing applications.

Factors To Consider When Choosing a Belt Material for Food Applications

Before we delve into comparing metal and PVC conveyor belts, it's essential to outline the key factors influencing this decision. Here are some crucial ones to consider:

Food Safety Standards Compliance

The chosen conveyor belt material must meet food safety standards such as FDA, EU, and HACCP guidelines.

Durability and Life Span

The belt material should be able to withstand the rigors of food processing, including significant wear and tear, high pressure, and continuous use.

Resistance to Contaminants

The belt material should resist build-up from food products and be able to be cleaned thoroughly to avoid bacterial growth.

Heat and Chemical Resistance

Depending on the nature of the food item, the belt material should resist heat and harsh cleaning chemicals.

Maintenance Requirements

Consider the time and cost required to maintain the belt material. Some materials may need more frequent cleaning or replacement.

Cost-Effectiveness

The initial and long-term costs of the belt material should align with the company's budget.

Environmental Impact

Consider the environmental footprint of the belt material, including its life cycle, recyclability, and disposal.

Product Suitability

The belt material should suit the food items it carries. Some materials are better suited for certain types of food products than others.

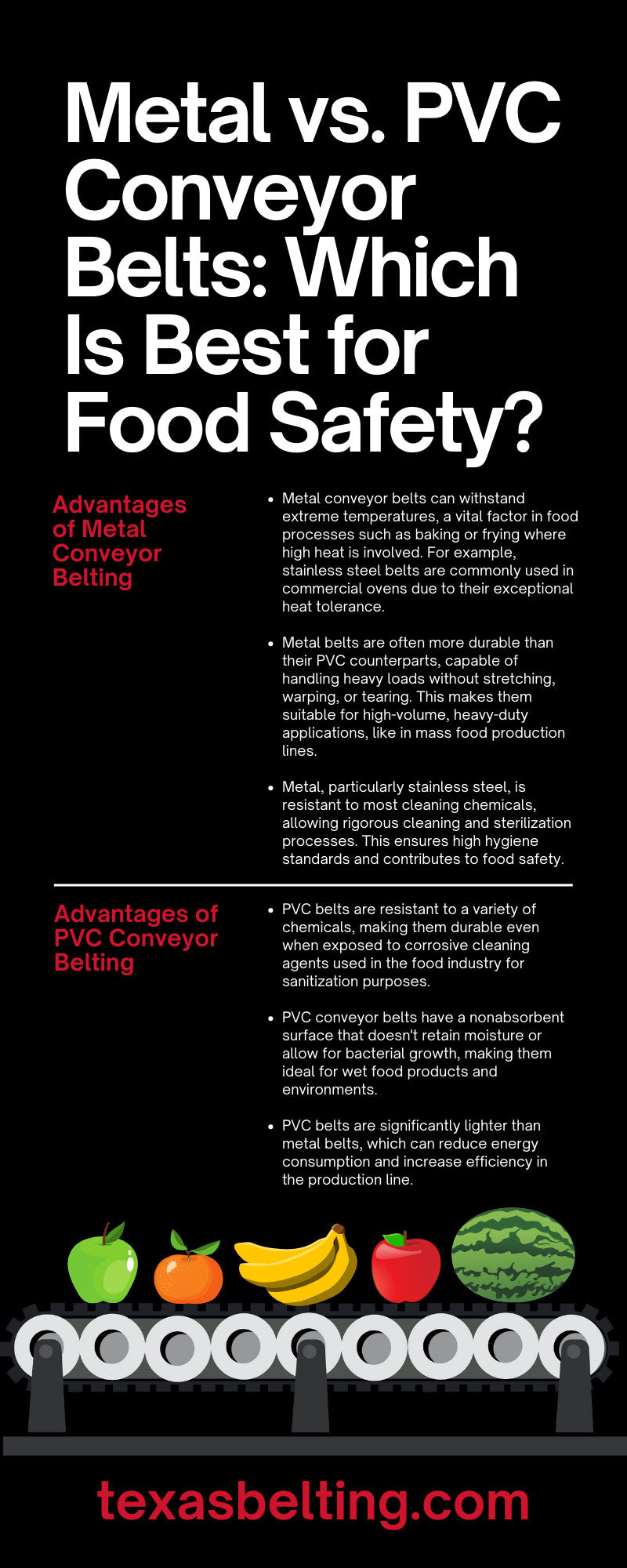

Advantages of Metal Conveyor Belting

As we examine the specifics of each conveyor belt type, we'll first focus on the metal conveyor belts. These belts are commonly used in several food industry applications and come with a host of benefits catering to different operational needs. Here are some key advantages you can expect with metal conveyor belting:

High-Temperature Resistance

Metal conveyor belts can withstand extreme temperatures, a vital factor in food processes such as baking or frying where high heat is involved. For example, stainless steel belts are commonly used in commercial ovens due to their exceptional heat tolerance.

Enhanced Durability

Metal belts are often more durable than their PVC counterparts, capable of handling heavy loads without stretching, warping, or tearing. This makes them suitable for high-volume, heavy-duty applications, like in mass food production lines.

Easy To Clean

Metal, particularly stainless steel, is resistant to most cleaning chemicals, allowing rigorous cleaning and sterilization processes. This ensures high hygiene standards and contributes to food safety.

Resistance To Sharp Edges

Metal belts are resistant to damage from sharp-edged products, an advantage in processes like meat and poultry processing where cutting and slicing are involved.

Magnetic Properties

Metal belts can be combined with magnetic systems to remove ferrous contaminants from the food, thus enhancing food safety.

Less Maintenance

Metal belts often require less maintenance compared to PVC belts since they are more resistant to wear and tear. This can result in lower long-term operational costs.

Advantages of PVC Conveyor Belting

Now, let's move on to PVC conveyor belting. PVC, short for polyvinyl chloride, is a type of plastic that offers its own unique benefits in the food industry. Here are some key advantages that come with PVC conveyor belting:

Chemical Resistance

PVC belts are resistant to a variety of chemicals, making them durable even when exposed to corrosive cleaning agents used in the food industry for sanitization purposes.

Flexibility

One key advantage of PVC conveyor belts is their flexibility. This makes them suitable for systems with many twists and turns and allows for easier installation and maintenance.

Nonabsorbent Surface

PVC conveyor belts have a nonabsorbent surface that doesn't retain moisture or allow for bacterial growth, making them ideal for wet food products and environments.

Lightweight

PVC belts are significantly lighter than metal belts, which can reduce energy consumption and increase efficiency in the production line.

Noise Reduction

PVC conveyor belts operate with less noise than metal belts, making for a safer and more comfortable work environment.

Cost-Effective

In terms of initial purchase cost, PVC conveyor belts are typically less expensive than metal belts. This makes them a more appealing choice for businesses operating on a tight budget.

Variety of Colors and Patterns

PVC belts are available in various colors and patterns, which can be a benefit for differentiating between product lines or for aesthetic purposes in visible sections of the processing line.

While PVC and metal conveyor belts have numerous advantages, it is important to remember that the best conveyor belt material choice depends on your food application's specific requirements.

How To Make the Right Decision for Your Business

When considering the choice between metal and PVC conveyor belting for your food application, it's critical to analyze your business needs thoroughly. Delve into your production line's specific requirements, the nature of the food you process, the safety standards you must adhere to, and your budget.

Consider using a weighted decision matrix to tally up the benefits of each material against your needs. Consulting with a conveyor belt expert can also provide valuable insights into the best material for your application. Remember, the optimal decision offers a fine balance between food safety, operational efficiency, and cost-effectiveness.

The question “Which conveyor belts are best for food safety: metal or PVC?” cannot be answered with a simple declaration. Both metal and PVC conveyor belts offer unique advantages that cater to different operational needs within the food industry.

Metal belts are suitable for heavy-duty applications and high-temperature processes. Conversely, PVC belts are ideal for applications with frequent belt changes, handling of wet food products, or where budget constraints are a concern.

It is crucial to thoroughly understand your production line's requirements and consult with conveyor belt experts like Texas Belting and Supply to make an informed decision. Ultimately, your choice should align with the needs of your food application, ensuring the highest standards of food safety and efficiency.