How To Identify V-Belt Types

A V-belt is a wedge-shaped belt manufactured out a rubber compound, reinforced with a tensile cord specifically engineered to transmit power into movement. V-belts can be found in driving mechanisms, such as engines in air compressors, fans, and pumps. They are available in a variety of sizes and materials to meet the needs of particular applications.

V-Belt Product Types

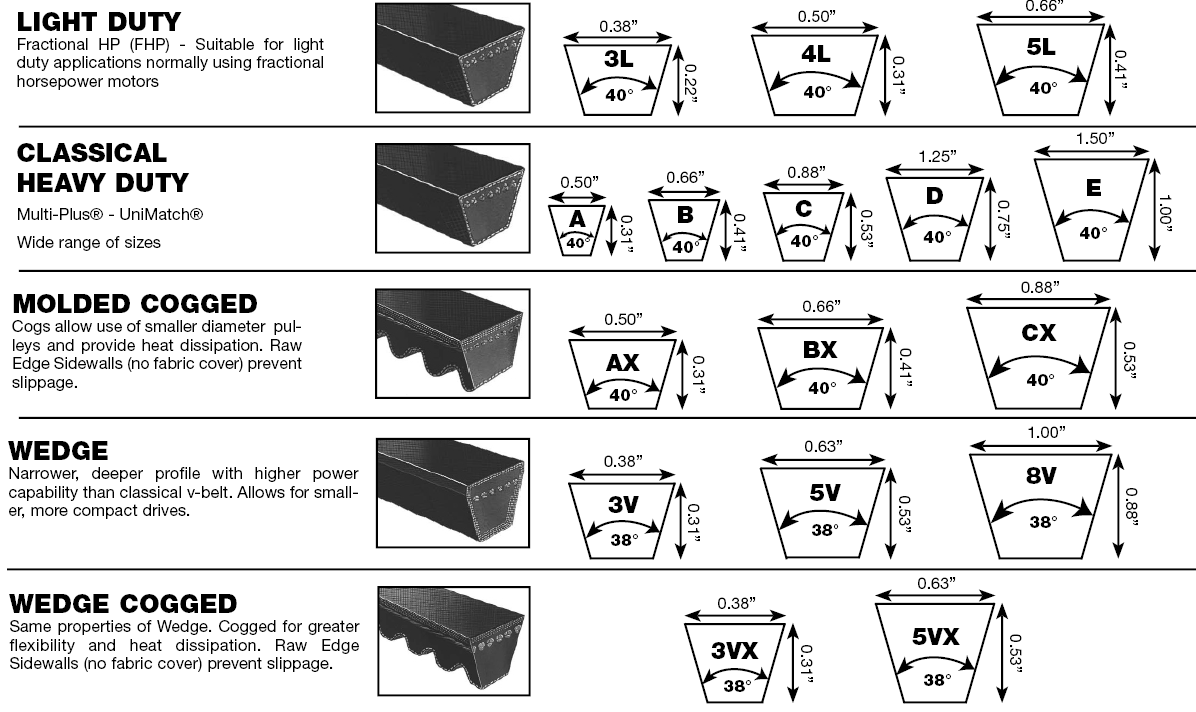

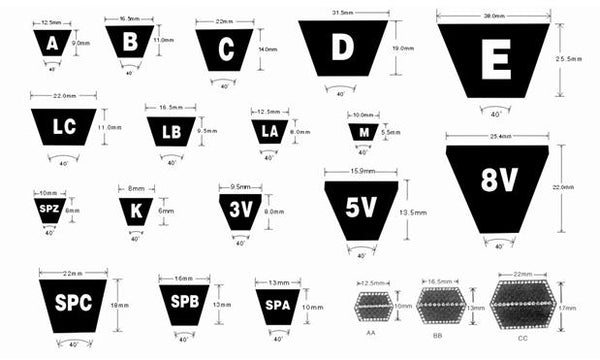

There are a number of possible types of belts available shown in the V-belt size chart

- Light Duty - Suitable for light duty applications normally using fractional horsepower motors

- Classical Heavy Duty - Wide range of sizes

- Molded Cogged - Cogs allow use of smaller diameter pulleys and provide heat dissipation; Raw Edge Sidewalls prevent slippage

- Wedge - Narrower, deeper profile with higher power capacity than classical v-belt; allows for smaller, more compact drives

- Wedge Cogged - Same properties as Wedge, but cogged for greater flexibility and heat dissipation

- Banded – Two or more v-belts joined to form a single belt allowing the belts to function as a single belt with equal load distribution and wear

How to Identify Types of V-Belt

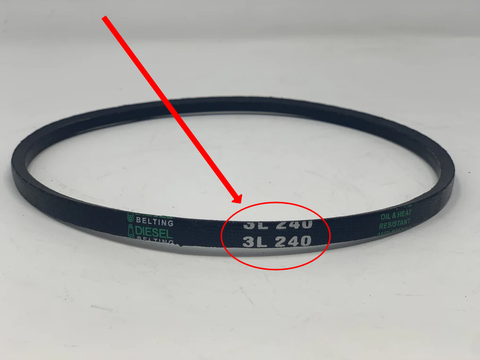

Belts with Branding

If the branding on the belt is still intact, the easiest way to identify the type of V-belt is to simply read the part number. Unfortunately, after hours of use the brand is often worn off and not legible. In this case, it becomes necessary to take note of the dimensions of the belt.

Belts without Branding

You then need to how to measure a V-belt. The following steps will allow you to do so:

Step 1: Determine Belt Cross Section

V-belt cross sections are categorized based on their top width and depth measurements. Each width/depth combination is labeled using a letter of the alphabet. For example, v-belts with 21/32 in. width and 7/16 in. depth is labeled a "B" belt. Specially designed Browning V-Belt Rules are also available with a gauge to help you select the correct belt type.

Step 2: Identify Belt Construction

V-belts are available in either wrapped or raw edge styles. A conventional wrapped v-belt will have an envelope of rubberized fabric covering the belt. A raw edge cogged v-belt will have exposed rubber sidewalls and molded cogs on the bottom that resemble teeth. The following characteristics may also be present, depending on the construction type: (Replace with baart graphic edited. wrapped v belt google image search first image)

- Rubberized fabric cover – Cover envelopes entire belt and protects the belt core

- Top fabric – Provides heat and oil resistance

- Load carrying section – Cords (also known as tensile members) give the ability to transmit power and ensure uniform load distribution

- Compression section – Elastomer resists compression fatigue and dissipates internal heat build-up, providing firm lateral pressure against sheave/pulley sidewall and distributes the load to the cords.

- Precision molded cogs – Provide additional flexibility, allowing for use of smaller pulley diameters, aiding in heat dissipation.

Step 3: Measure V-belt length

The most difficult part of identifying a V-belt type is measuring the length. There is no precise method that is practical to perform in the field for V-belt measurement. Precise measurement requires a measuring fixture with pulleys of prescribed dimension and the ability to apply a specific tension to the belt according to ARPM (Association for Rubber Product Manufacturers) standards for the given belt section.

Additionally, there are a number of terms used in the industry to describe length (e.g. inside length, outside length, pitch length, effective length) making it very confusing.

Some belt providers instruct end users to utilize tapes to measure outside length. While this method can approximate belt length, it can still be off by inches. If the drive has ample installation and take-up range, using a tape can yield a belt that will fit the drive in many cases, however, there is no guarantee it is the optimum length designed for the drive.

Measurements

There are a few measurements needed to help locate the correct part number for your belt. With these dimensions and knowledge of the material we can reference your belt across multiple manufacturers.

Top Width - The top width of the belt is measured in millimeters. For the most accurate use a caliper to get a precise measurement. This measurement can vary depending on the wear of the belt and in many cases can be cut to size.

Pitch - The pitch of a belt is the measurement between teeth. This measurement is taken from the center of one tooth to the next. Additionally the shape of the tooth can be used as an identifier for the belt. Reference different belt profiles and link to product pages.

Outside Circumference - The outside circumference is the distance taken from one section of the belt completely around the belt. We recommend using a soft tape measurer for the most accurate measurement.

Step 4: Label the Drive

Finally, to avoid the issue of identifying the v-belt each time it needs to be replaced, a good maintenance practice is to properly label the drive with the correct belt part number. Use an adhesive sticker or any type of permanent signage where you can easily read the belt part number, making it easy to obtain belts in the future. Recording the date when the belts were installed can also enhance your maintenance program with increased uptime by knowing when to replace belts before they fail.

Serpentine Belts(Automotive Belts)

Click here for our selection of serpentine belts.

Serpentine belts have two critical measurements; the number of ribs and the outside circumference of the belt in millimeters. An example part number is "11PK2800". If we break this part number down each section serves a purpose.

"11PK" - This section of the part number shows us that the belt has 11 ribs.

"2800" - This section of the part number shows us that the belts outside circumference is 2800 millimeters.

Timing Belts

Click here for our selection of timing belts.

Timing belts have three critical measurements; the pitch, outside circumference and the width of the belt in millimeters. An example part number is "1000-8M-12" If we break this part number down each section serves a purpose.

"1000" - This section of the part number shows us that the belt's outside circumference is 1000 millimeters.

"8M" - This section of the part number refers to the pitch of the belt or the distance measured from the middle of one tooth to the middle of the next.

"12"- This section of the part number refers to the top width of the belt in millimeters.

V-Belts

Click here for our V-Belt identification page.

There are several part numbers for standard v-belts. For this reason we've created a separate page for identifying these part numbers at the link above.