Conveyor belt design varies depending on the industry. For example, a rock quarry may need long telescoping belts and tall, cleated incline conveyors. That setup would be very different from a plant making tortillas, which requires heat- and oil-resistant food-grade belting.

There are two main options for companies looking to implement a conveyor belt system: The first option is to purchase an off-the-shelf design that comes with a predetermined setup. The second option is to hire a third-party company to design a custom conveyor system. Read our guide to custom conveyor system design and learn why many businesses prefer this option.

Why You Need a Conveyor System

If you’re considering investing in a conveyor system, you probably already know some of the ways that conveyor systems make businesses more efficient. However, there are probably some factors you haven’t considered, and these may explain why choosing a custom design is the better option.

Precise Replication

One benefit of using conveyor systems is that machines can do thousands of tasks exactly the same way, every operation cycle. Even experienced human workers will make mistakes, but machines don’t make mistakes unless their human operators fail to maintain them. Therefore, automating the process helps ensure that every product or raw material is uniform.

Longer Work Cycles

Machines do need breaks to avoid overheating, but they don’t take shifts and require lunch breaks. When you integrate a conveyor system into your operations, you’re actually creating a longer workday. That means you can take more orders and complete them more efficiently.

Reduced Staffing Needs

If you’re finding that staffing overhead costs are weighing your operation down, automation is the way to go. With conveyor systems taking over much of the hands-on production and transportation processes, your employees can focus on more essential tasks.

The Advantages of Custom Conveyor Design

There’s a lot to consider when deciding what kind of conveyor system to invest in. Below are some of the advantages of choosing a custom design as opposed to a pre-made set of equipment.

Designed for Your Space

Every industrial setting looks a little different. Depending on your industry, most of your operations could be either indoors or outdoors. You may have drop-off and pick-up sites to coordinate with. That’s not even including the different workspaces for production, packaging, sorting, and quality checking.

With a custom design, you can have a conveyor system that makes it faster for you to move materials between these different spaces. Instead of struggling to fit pre-made equipment into your existing space, you’ll have a design that fits seamlessly.

Designed for Your Product

While it’s fine to use a cookie-cutter conveyor system for, well, cookies, other types of products require a more specialized design. This may be especially true if you work with chemicals or in the pharmaceutical industry, where innovation is a key part of what your business does. Existing conveyor systems might not be able to account for your product’s needs.

Designed for Your Operations

If you invest in a custom conveyor system, your engineers can make sure it integrates with your company’s existing methods of operation. You may have a specific order for transporting materials around the worksite, and using a pre-packaged set of equipment could result in jerry-rigging instead of optimal design.

What To Consider When Designing a Custom Conveyor System

This last section of our guide to custom conveyor system design is all about planning an optimal design. When you work with an engineer to draft the conveyor system, these are some of the questions they’ll ask and how the answers will affect the design.

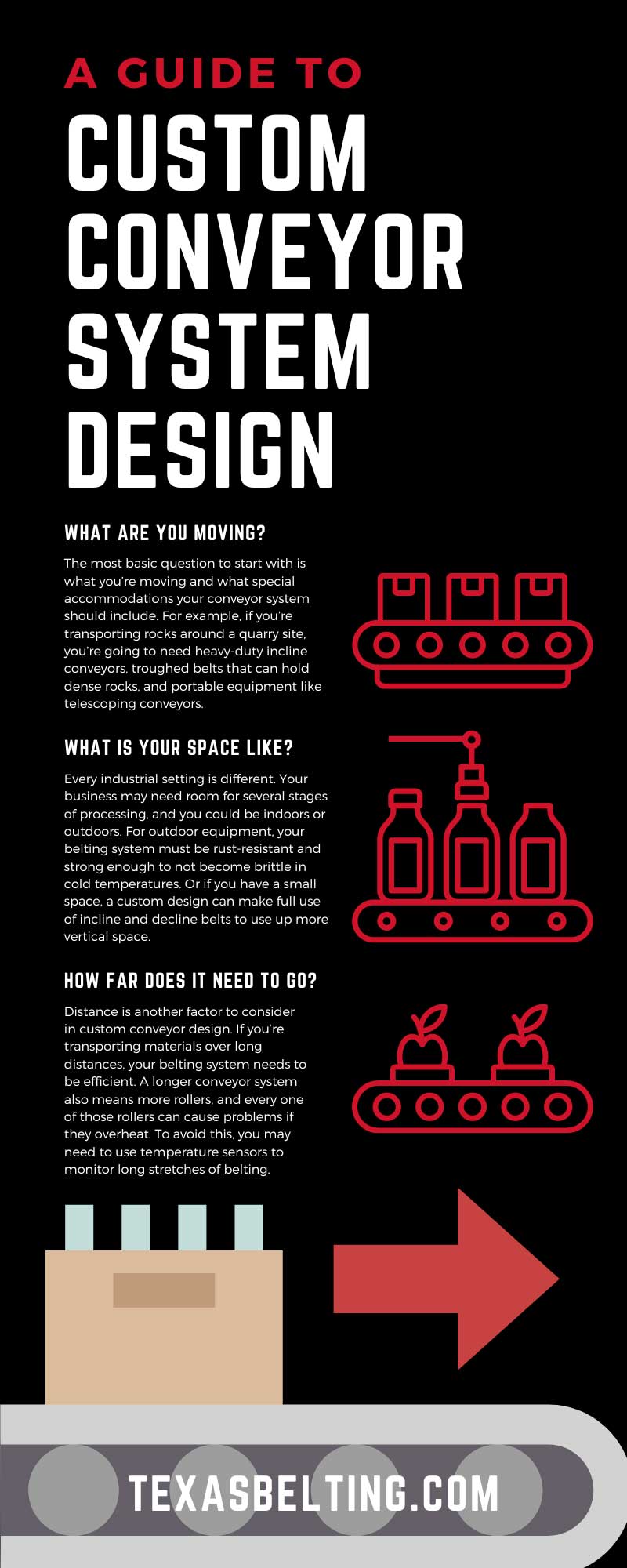

What Are You Moving?

The most basic question to start with is what you’re moving and what special accommodations your conveyor system should include. For example, if you’re transporting rocks around a quarry site, you’re going to need heavy-duty incline conveyors, troughed belts that can hold dense rocks, and portable equipment like telescoping conveyors.

And going back to our tortilla plant example, a food-processing plant is going to need very different kinds of belting. You may not just be moving the product—you might also be making it on the conveyor belt. This means your belting will need to accommodate fragile food products and be easy to clean.

What Is Your Space Like?

As we mentioned earlier, every industrial setting is different. Your business may need room for several stages of processing, and you could be indoors or outdoors. For outdoor equipment, your belting system must be rust-resistant and strong enough to not become brittle in cold temperatures. Or if you have a small space, a custom design can make full use of incline and decline belts to use up more vertical space.

How Far Does It Need To Go?

Distance is another factor to consider in custom conveyor design. If you’re transporting materials over long distances, your belting system needs to be efficient. A longer conveyor system also means more rollers, and every one of those rollers can cause problems if they overheat. To avoid this, you may need to use temperature sensors to monitor long stretches of belting.

What To Look For in a Custom Conveyor Designer

When you’re shopping for a custom conveyor system designer, you should get as much expertise for your money as possible. Some things to consider about your potential designer include the following:

- What kind of experience do they have?

- Do they specialize in the kind of conveyor you need?

- Are their previous clients happy with their work?

- How does their pricing compare to their competitors?

- What kind of software do they use to design their products?

- Are there any limits to the kinds of systems they can design?

Remember—having a good presentation for prospective clients isn’t enough. You need to find a company that can follow through on its promises, so don’t rush the decision process.

Finding Quality Belting

Though your conveyor system designer will be able to create the machinery you need, you may still need a belting partner. Texas Belting and Supply carries hundreds of styles of belting for all kinds of industrial needs. Our belts are perfect for troughing, long-distance transportation, food preparation, and sterile pharmaceutical production. We even carry heavy-duty urethane belts, including plastic chain. Contact us today to let us outfit your operation with long-lasting belting.