The effectiveness and efficiency of your machinery in packaging production can significantly influence your bottom line. Folder gluers are among these machines that play a crucial role in packaging. Understanding how to optimize your folder gluer machines can help increase productivity, reduce waste, and ultimately enhance the profitability of your operations.

We aim to equip you with practical techniques and strategies to maximize the performance of your folder gluer machines. From the importance of regular maintenance to leveraging technology, learn the various aspects that contribute to the optimal functioning of your machinery. Unlock the full potential of your folder gluer machine and elevate your packaging production process.

Understanding the Basics of a Folder Gluer

A folder gluer machine is a fundamental component in the packaging production process. It is responsible for folding and gluing flat sheets or cardboard into specific shapes to form boxes, cartons, or other forms of packaging. The process begins with the machine accurately creasing the flat sheets at specified positions. Next, the sheets are folded and glued together, resulting in a well-assembled package.

The significance of a folder gluer machine in packaging production cannot be overstated. It provides incredible speed and precision, enabling a rapid and flawless production of packages. Furthermore, it is highly versatile and capable of creating a broad range of package designs to cater to diverse packaging needs. Its role in maintaining production efficiencies and meeting customer demands makes it indispensable in the packaging industry.

The Importance of Regular Maintenance and Cleaning

Regular maintenance and cleaning of your folder gluer machine are paramount for optimal operation. Ensuring all components function smoothly is fundamental to maintaining the efficiency and longevity of your machinery. Regular cleaning helps remove dust and adhesive remnants that might otherwise accumulate over time and interfere with the machine's operation. Such obstructions can lead to mechanical failures or inaccurate folding and gluing, compromising the quality and consistency of your packaging.

Routine maintenance, on the other hand, allows for timely identification and rectification of potential mechanical issues before they escalate into severe problems. By keeping the folder gluer machine belts and other parts in excellent condition, you not only prolong the machine's life span but also ensure it operates at peak performance. This, in turn, results in high production speeds, minimal waste, and high-quality output, ultimately increasing profitability.

Techniques for Enhancing Efficiency

While keeping your folder gluer machines clean and well maintained is vital, numerous other techniques can significantly enhance their efficiency. Below, we'll discuss several practices that can help you get the most out of your folder gluer machines.

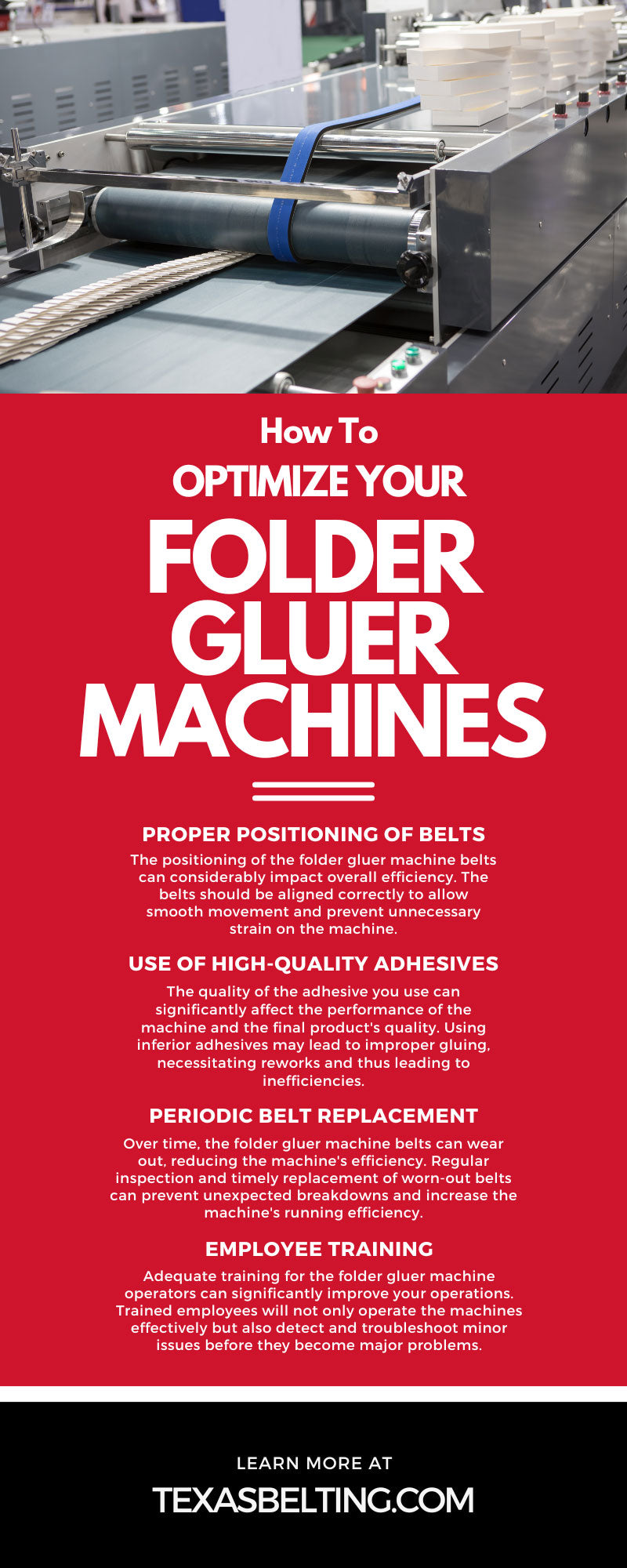

Proper Positioning of Belts

The positioning of the folder gluer machine belts can considerably impact overall efficiency. The belts should be aligned correctly to allow smooth movement and prevent unnecessary strain on the machine.

Use of High-Quality Adhesives

The quality of the adhesive you use can significantly affect the performance of the machine and the final product's quality. Using inferior adhesives may lead to improper gluing, necessitating reworks and thus leading to inefficiencies.

Periodic Belt Replacement

Over time, the folder gluer machine belts can wear out, reducing the machine's efficiency. Regular inspection and timely replacement of worn-out belts can prevent unexpected breakdowns and increase the machine's running efficiency.

Optimizing Machine Settings

Different packaging materials and designs may require different machine settings. Tailoring the machine settings to suit the specific task can significantly enhance the folder gluer's effectiveness.

Employee Training

Adequate training for the folder gluer machine operators can significantly improve your operations. Trained employees will not only operate the machines effectively but also detect and troubleshoot minor issues before they become major problems.

Leverage Technology

In today's technologically driven world, leveraging advanced expertise can significantly enhance the performance of your folder gluer machines. The following points explain some ways to harness technology for optimization.

Utilize Automation

Automated folder gluer machines can significantly enhance your production efficiency. They reduce human error and ensure consistency in packaging quality. Automation also reduces the fatigue and monotony associated with manual operations, freeing your employees from tasks requiring critical thinking.

Embrace Data Analytics

Machine learning and data analytics can help you better understand your folder gluer machines' performance. By gathering and analyzing data, you can identify patterns, inefficiencies, and areas for improvement. Data analytics can provide insights into the optimal positioning of folder gluer machine belts, the best adhesives to use, ideal machine settings, and the right time to replace parts.

Adopt Predictive Maintenance

Rather than performing maintenance based on a set schedule, predictive maintenance utilizes sensor data to monitor the condition of your folder gluer machine in real time. This enables you to identify potential issues before they become significant problems, ensuring your machine operates at peak efficiency and reduces unexpected downtime.

Invest in Software Solutions

Numerous software solutions can help you optimize the settings of your folder gluer machines for different packaging materials and designs. These tools can also integrate with your inventory management system to automatically reorder supplies like adhesives or folder gluer machine belts when they run low.

Troubleshooting Common Issues

Despite your best preventive efforts, folder gluer machines can still encounter issues. Knowing how to troubleshoot common problems is crucial for maintaining an efficient and productive operation.

Misalignment of Glued Parts

This often results from incorrect belt positioning on the folder gluer machine. Check the alignment of the folder gluer machine belts and make necessary adjustments to ensure straight and precise folding and gluing.

Inconsistent Adhesion

This could be due to the use of low-quality adhesives or incorrect machine settings. Ensure you're using high-quality adhesives and adjust the machine settings if necessary. Regularly inspecting and cleaning the adhesive application components can also help maintain consistent adhesion.

Machine Slowdown or Stops

This could be due to worn or damaged folder gluer machine belts. Regular inspection and timely replacement of the belts can prevent these issues. If the machine continues to slow down or stop, consider consulting an expert or the machine's manufacturer.

Excessive Noise During Operation

This might indicate a mechanical issue or misalignment within the machine. Check all moving parts, including belts, for proper alignment and signs of wear or damage. Lubricate the moving parts if necessary.

If you cannot resolve any problems, don't hesitate to contact a professional or your machine's manufacturer for assistance.

Understanding how to optimize your folder gluer machines is crucial to achieving peak efficiency, high-quality output, and ultimately, improved profitability. It's a comprehensive process that encompasses many different strategies and techniques. The productivity of your packaging operations is directly tied to the efficiency of your machinery. Therefore, a well-optimized folder gluer machine is a valuable asset and a strategic tool that can significantly enhance your competitive edge in the packaging industry.