In the fast-paced world of logistics and distribution, improving supply chain efficiency with conveyor systems has emerged as a game-changer. The intricate dance of moving goods seamlessly from production to consumers is a critical component of any business, with delays causing significant downstream repercussions.

Harnessing the potential of conveyor systems can dramatically streamline this process. These systems have numerous benefits you don't want to miss out on! Let's take a look at how your business's supply chain can increase efficiency with the help of conveyor systems.

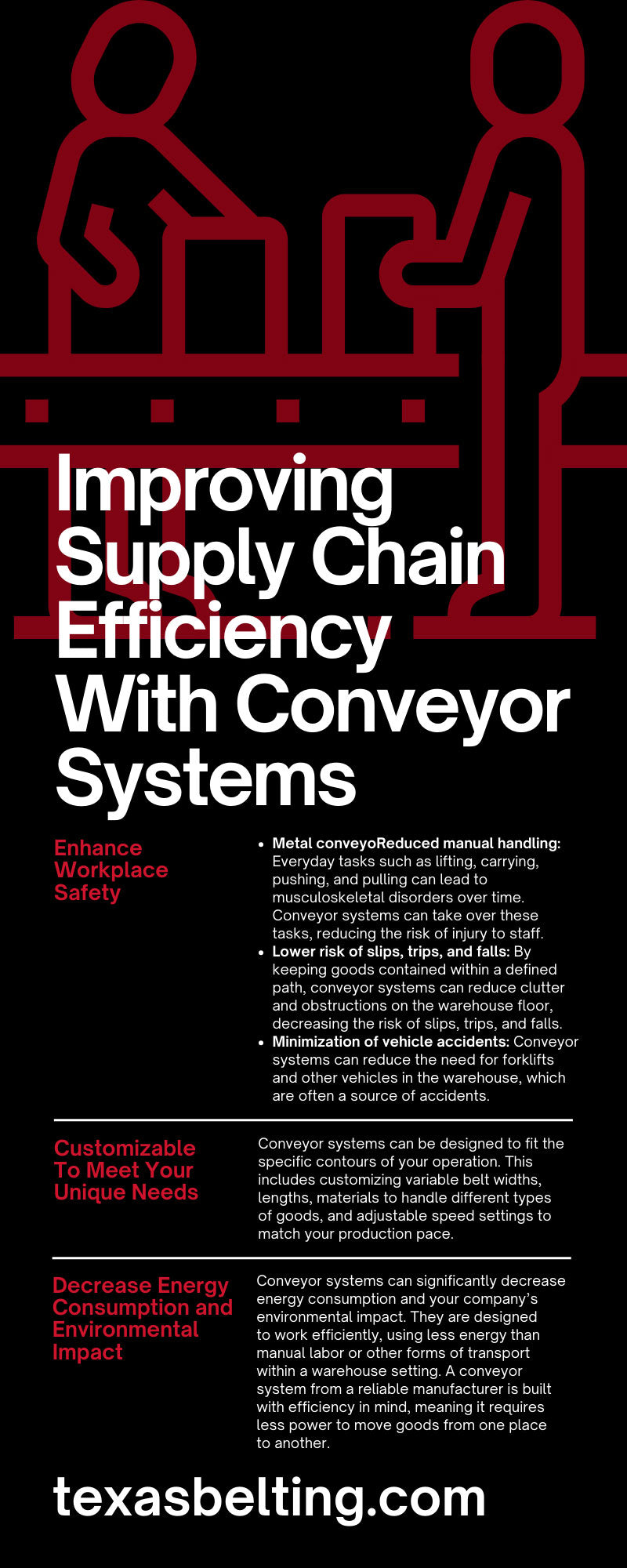

Enhance Workplace Safety

When appropriately utilized, conveyor systems can significantly enhance safety in the workplace. They help minimize the risks associated with manual handling tasks, a common source of workplace injuries.

- Reduced manual handling: Everyday tasks such as lifting, carrying, pushing, and pulling can lead to musculoskeletal disorders over time. Conveyor systems can take over these tasks, reducing the risk of injury to staff.

- Lower risk of slips, trips, and falls: By keeping goods contained within a defined path, conveyor systems can reduce clutter and obstructions on the warehouse floor, decreasing the risk of slips, trips, and falls.

- Minimization of vehicle accidents: Conveyor systems can reduce the need for forklifts and other vehicles in the warehouse, which are often a source of accidents.

By choosing reliable conveyor manufacturers, businesses can ensure they are investing in high-quality, durable conveyor systems that not only improve efficiency but also contribute to a safer working environment.

Increase Productivity and Efficiency

Conveyor systems are a powerhouse when it comes to increasing productivity and efficiency, offering a multitude of benefits that streamline operations.

- Continual operation: Conveyor systems can run continuously, taking the burden off your workforce and avoiding the downtime associated with breaks or shift changes. This enables a consistent flow of goods, enhancing output and productivity.

- Versatility: Conveyor systems can handle various materials, from small, delicate items to larger, heavier goods. This flexibility means they can be integrated into almost any production or distribution process, enhancing efficiency across the board.

- Reducing wasted time: Conveyor systems streamline the movement of goods, reducing the time wasted transporting items from one location to another. This allows staff to focus on more critical tasks, boosting overall operational efficiency.

A quality conveyor system can be a significant investment, but the productivity and efficiency gains it provides can quickly justify the initial outlay.

Improve Accuracy and Speed

Enhancing accuracy and speed in business operations is another advantage of conveyor systems. With these systems, businesses can automate their processes, significantly reducing the margin for human error and ensuring a higher standard of precision.

- Elimination of human error: Manual handling of goods often results in errors, from simple miscounts to misplaced items. Conveyor systems can automate these tasks, offering a level of precision that human workers may not consistently achieve.

- Streamlined sorting and distribution: Conveyor systems can be equipped with advanced features such as barcodes or RFID scanning technologies. These features facilitate precise sorting and rapid distribution of goods, ensuring every product reaches its correct destination quickly and accurately.

- Faster production times: Conveyor belts are designed to operate at optimal speeds without compromising safety or efficiency. This allows businesses to expedite their production processes, resulting in quicker turnaround times and improved customer satisfaction.

By leveraging the capabilities of conveyor systems, businesses can elevate their operational efficiency, speed, and accuracy to new levels.

Customizable To Meet Your Unique Needs

One of the standout advantages of conveyor systems is their ability to be customized to meet the unique needs of your business. Conveyor systems can be designed to fit the specific contours of your operation. This includes customizing variable belt widths, lengths, materials to handle different types of goods, and adjustable speed settings to match your production pace.

Advanced features, like weighted scales, can also be included to further refine your processes. By tailoring your conveyor system to align closely with your operational requirements, you can optimize efficiency, safety, and productivity, delivering notable improvements in your overall supply chain performance.

Decrease Energy Consumption and Environmental Impact

Conveyor systems can significantly decrease energy consumption and your company’s environmental impact. They are designed to work efficiently, using less energy than manual labor or other forms of transport within a warehouse setting. A conveyor system from a reliable manufacturer is built with efficiency in mind, meaning it requires less power to move goods from one place to another.

Additionally, by reducing the need for forklifts and other vehicles that emit harmful pollutants, conveyor systems contribute to a reduction in carbon footprint. Moreover, some conveyor systems can even be fitted with energy-saving features, such as sleep modes that conserve power when the system isn’t in use, further contributing to your company’s energy efficiency. Thus, investing in conveyor systems is not only a step toward increased productivity but also a move toward sustainability and environmental responsibility.

Selecting the Perfect Conveyor System for Your Business

Choosing the ideal conveyor system that aligns with your business needs doesn't have to be a daunting task. Here are some key points to consider when selecting the perfect conveyor system.

Understand Your Business Needs

Before you start looking for a conveyor system, it's essential to understand your business's specific needs. Consider the type of products you handle, their weight, size, and any special requirements they may have. Ensure the chosen conveyor system can accommodate these factors.

Consider the Environment

The physical conditions in your workspace can influence the type of conveyor system you need. Factors such as temperature, moisture, and the presence of any corrosive substances should be taken into account.

Prioritize Quality and Durability

The conveyor system is a significant investment, and it should stand the test of time. Prioritize quality and durability—this is where partnering with reliable PVC belt manufacturers comes into play. Such manufacturers provide robust and high-performing conveyor systems that can withstand heavy usage over time.

Check for Customization Options

Every business is unique, and so are its operational needs. Opt for a conveyor system that offers customization options to meet your specific requirements. This could include adjustable speeds, various belt materials, and additional technological features, like barcode scanners.

Consider the After-Sales Support

The relationship with your conveyor system provider shouldn't end at the point of sale. Consider their after-sale services and support. This includes maintenance services, availability of spare parts, and their response time to any technical issues. A provider with strong after-sale support will ensure your operations are not significantly affected by any potential system breakdowns.

Improving supply chain efficiency with conveyor systems is a transformative strategy that businesses should seriously consider. These systems offer many benefits, ranging from increased safety and productivity to enhanced accuracy and speed. This technology and equipment should not be viewed merely as an expense but as a strategic investment in improving your supply chain operations.