While 3D printing has been in the mainstream for a handful of years, the actual technology has been around since the 1980s. Since then, engineers have discovered a number of improvements to the technology, including adding conveyor belts to 3D printers. Discover how the 3D printing industry uses conveyor belts.

What Is 3D Printing?

3D printing may sound like something from a sci-fi film, but it’s very real. If you think about it, printing on a piece of paper is 2D printing since a piece of paper only has an X and Y axis. 3D printing adds a third dimension: the Z axis. A third dimension allows 3D printers to create fully 3D objects. The only limit to the size of the object is the printer itself.

How Does 3D Printing Work?

To begin 3D printing, you first need a computer and file you want to print. The file communicates to the printer how to create the desired shape. Most 3D printers use a technique called layering, where they add layers of material until they create the desired shape. This would be like if an artist made a sculpture by layering up bits of clay instead of chipping away at a block of marble.

The Benefits of 3D Printing

Many industries have adopted 3D printing because of how useful it is. Some benefits include the ability to print on-demand parts, customization, and a lack of waste. We’ll dive into these benefits in the sections below.

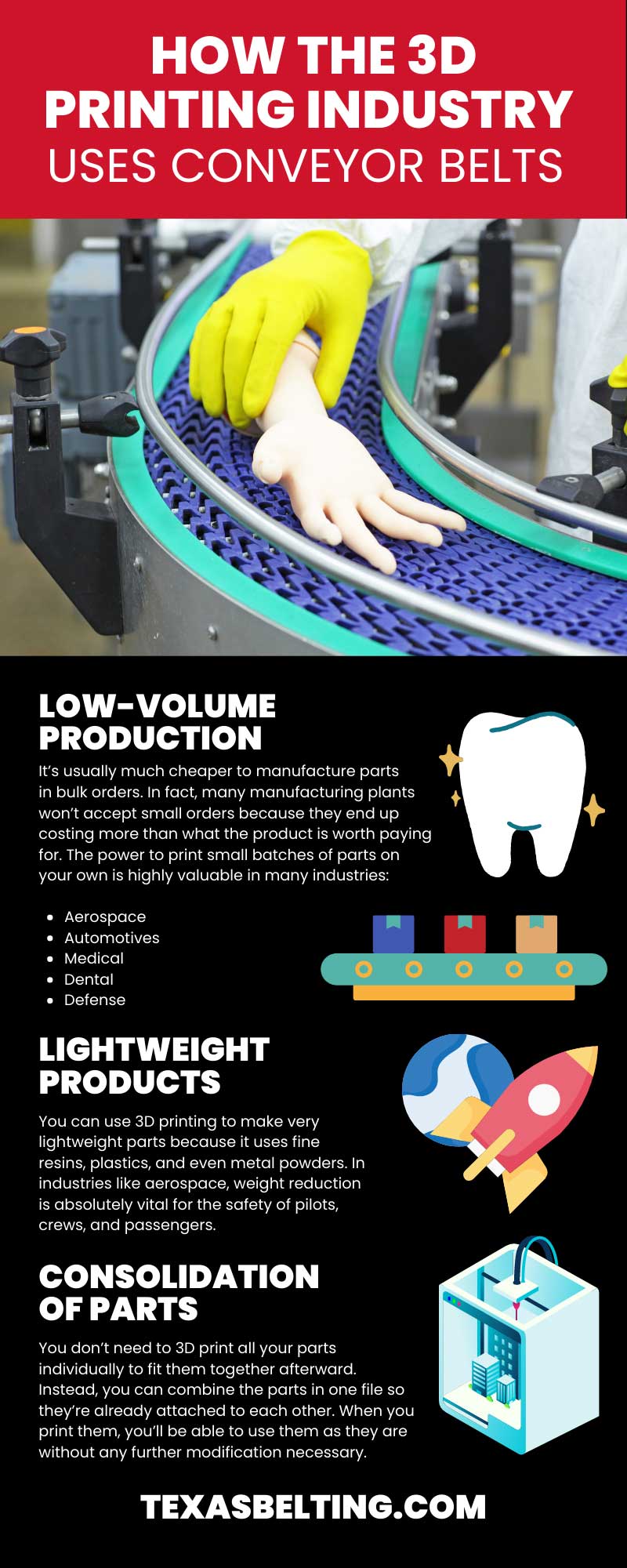

Low-Volume Production

It’s usually much cheaper to manufacture parts in bulk orders. In fact, many manufacturing plants won’t accept small orders because they end up costing more than what the product is worth paying for. The power to print small batches of parts on your own is highly valuable in many industries:

- Aerospace

- Automotives

- Medical

- Dental

- Defense

Lightweight Products

You can use 3D printing to make very lightweight parts because it uses fine resins, plastics, and even metal powders. In industries like aerospace, weight reduction is absolutely vital for the safety of pilots, crews, and passengers.

Consolidation of Parts

You don’t need to 3D print all your parts individually to fit them together afterward. Instead, you can combine the parts in one file so they’re already attached to each other. When you print them, you’ll be able to use them as they are without any further modification necessary.

3D Printing Repairs

One of the most unique ways that industries use 3D printers is to print repairs right on top of damaged parts. Since 3D printing works by adding layers of material, you can print layers of repair product right on top of a turbine blade or other piece of expensive equipment. These repairs can easily extend the life of machinery by many years.

Low Waste Production

Another reason manufacturers love 3D printing is that it generates very little waste. Since the machine builds up the printed object through layers, there’s no need to use additional material. Waste is usually limited to tiny sprues or particles from sanding finished prints.

3D Printing and Conveyor Belts

A major drawback to 3D printing is that you’re limited to the size of your machine. Under normal circumstances, you can’t print something larger than what your machine can handle. However, adding a conveyor belt to your printer can drastically change your printing capacity.

Larger Print Sizes

Unlike normal 3D printers, a printer with a conveyor belt needs to be set at an angle. This way, the printer prints right onto the moving belt. The belt moves the object away from the printer at exactly the right speed, creating one continuous object. The longer your belt, the larger the pieces you can print. With the right equipment, you can even print objects longer than your belt—just be careful!

Continuous Production

The 3D printing industry also uses conveyor belts to increase production speed. You can print individual pieces non-stop with a belt attached to your printer. The belt will move each piece out of the way for the next one.

Faster Quality Checks

Adding a conveyor belt to your printing operation gives you all the benefits of modern industrialization, even if you’re printing small batches. One example is quality checks. If you combine a backlight with your conveyor belt printer, you can easily inspect pieces for flaws while they’re still on the belt.

Nonstick Coatings

Depending on the material you’re using to print objects, you could have an issue with the printed objects sticking to the belt. However, you can get high-quality manufacturing belts with special coatings that resist heat and adhesives from Texas Belting and Supply.

How To Shop for a 3D Belt Printer

Before shopping for a 3D belt printer, take note of a few important things. First of all, both hobbyist and industrial belt printers are on the market. Hobbyist printers are smaller and much less expensive than their industrial counterparts.

Know Your Printing Material

Some printers are more versatile than others. You may need to shop for specific models if you want to print metal parts with metallic powders. Not every 3D printer—even industrial ones—can handle every type of printing material.

Consider Belt Specifications

Ask yourself how long you want the printer belt to be. Are you trying to connect it with other belting systems? Do you need any special coatings on your belt to cool and cure parts? Talk to a professional conveyor belt supplier about your business’s needs. They can guide you toward the optimal setup for your operation.

The Industrial Belting Experts

Texas Belting and Supply is proud to serve a variety of industries with high-quality conveyor belts. We carry plastic, urethane, and PVC belting in all shapes and sizes. Many of our belts come with special coatings to speed up belt cleaning and prevent carryback. We also supply businesses with industrial-grade incline and decline belting, food-grade belts, and equipment belts for folder gluer machines and bandsaws.

If you’re new to 3D belt printing, let us guide you through the process. Contact us today to find out how our belting can increase your printer’s output and efficiency.